-

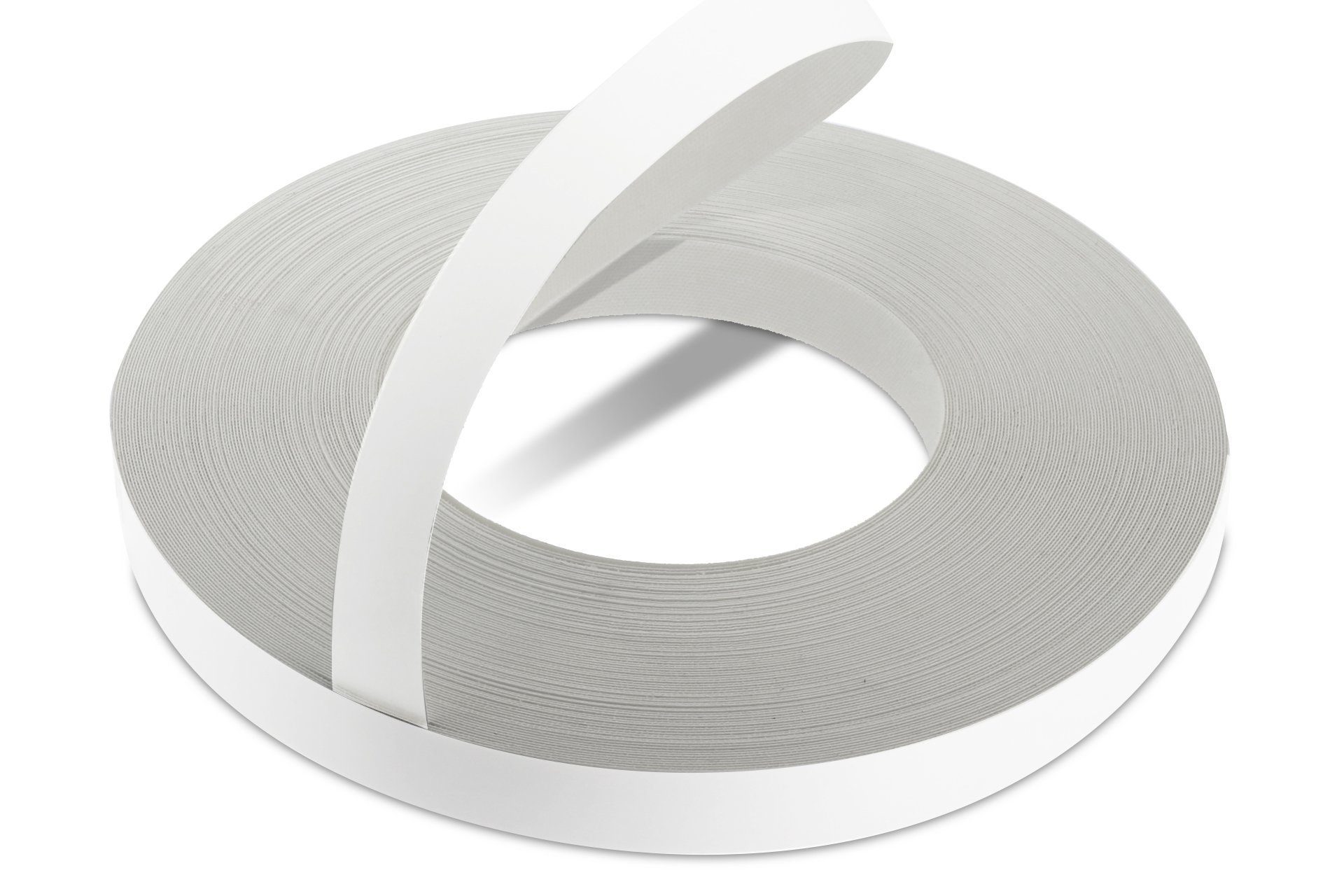

WoodPress® White Matt Melamine Edge Banding - Pre-Glued Iron-On Tape - 50m Length Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT)

WoodPress® White Matt Melamine Edge Banding - Pre-Glued Iron-On Tape - 50m Length Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT) -

WoodPress® White Pearl Melamine Edge Banding - Pre-Glued Iron-On Tape 50m Length Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT)

WoodPress® White Pearl Melamine Edge Banding - Pre-Glued Iron-On Tape 50m Length Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT) -

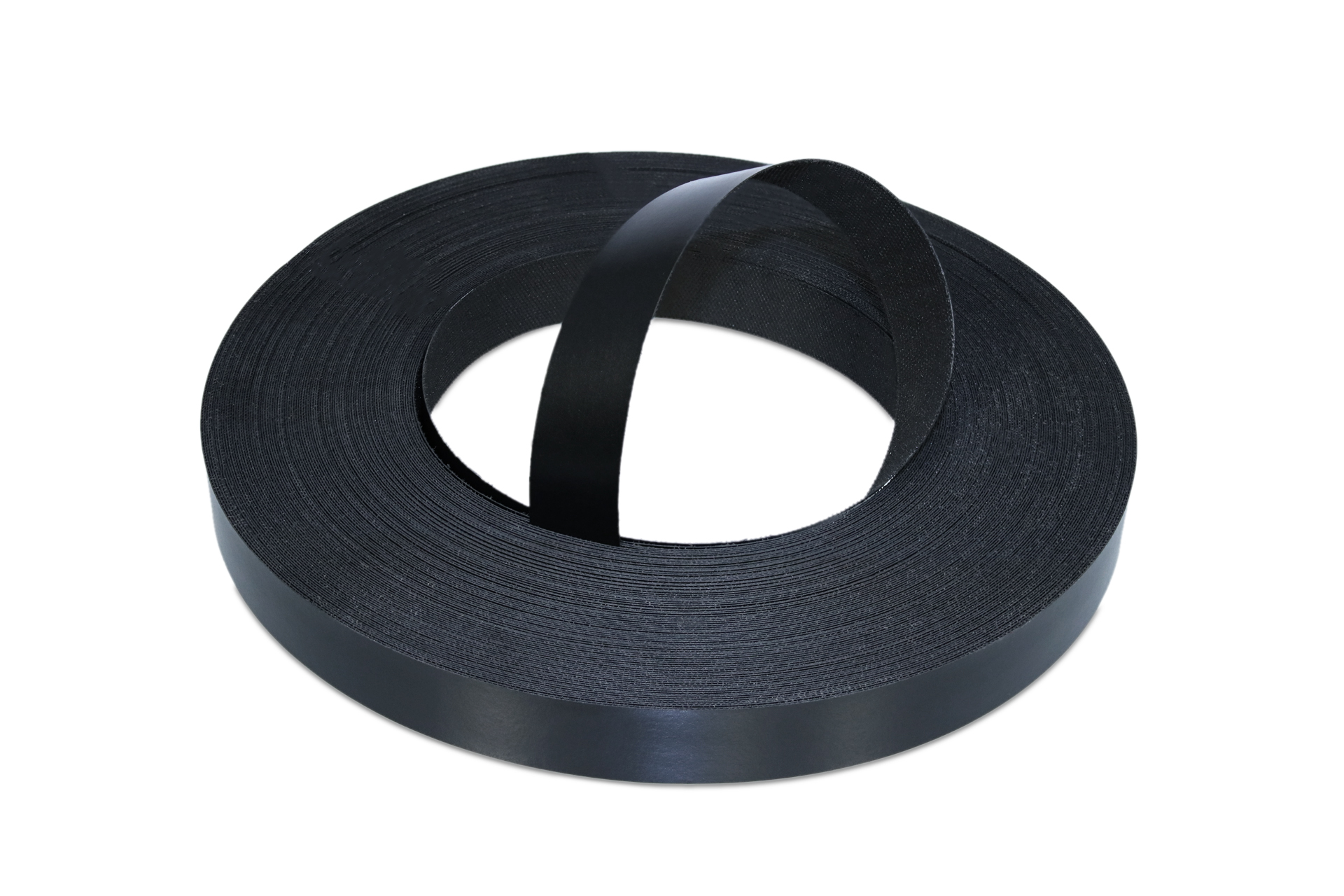

WoodPress® Black Matt Melamine Edge Banding - Pre-Glued Iron-On Tape - 50m Length Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT)

WoodPress® Black Matt Melamine Edge Banding - Pre-Glued Iron-On Tape - 50m Length Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT)

6 Best Practice For Applying Edge Banding

When applying edge banding it is important to remember that proper preparation and technique are essential for ensuring a durable, high-quality result…

Choose the Right Edge Banding Material

Edge banding comes in many varieties, usually organised as wood veneer and melamine; choosing the right one is down to personal preference and the other materials used in the project.

Prepare the Surface

When applying edge banding on an MDF board, no preparation is necessary, but if working with plywood or other surfaces, lightly sanding the surface and giving it a quick brush down will ensure the edge banding bonds more securely.

Use the Right Adhesive

In this guide we are covering best practices for pre-glued iron-on edge banding, i.e., coated with heat-activated glue on one side. However, for unglued edge banding, you can use contact cement.

Pro Tip: If you are having trouble choosing the correct adhesive for your edge banding, you can reference our wood glue guide: The Ultimate Guide To Wood Glues

Trim Excess Material

After the edge banding is securely in place, trim the overhanging edges. A specialised edge banding trimmer or a sharp utility knife ensures clean and precise cuts. Be careful not to damage the surface of the board.

Sand and Smooth the Edges

Use fine-grit sandpaper (e.g., 180-220 grit) to smooth the edges and remove any sharp or uneven areas. This step is crucial for achieving a seamless look and feel.

Seal or Finish

Depending on the material and the project, apply a protective finish to the edge banding and the board. This step enhances durability and ensures the edge banding blends seamlessly with the rest of the piece.

Common Mistakes to Avoid

- Skipping Surface Preparation: Neglecting this step can lead to poor adhesion.

- Using Excessive Heat: Overheating can warp or melt the edge banding.

- Rushing the Process: Take your time to ensure each step is completed with precision.

Conclusion

By following these best practices, you can achieve a professional-grade finish with your edge banding projects. With proper care and attention to detail, your woodworking creations will look polished and stand the test of time.