-

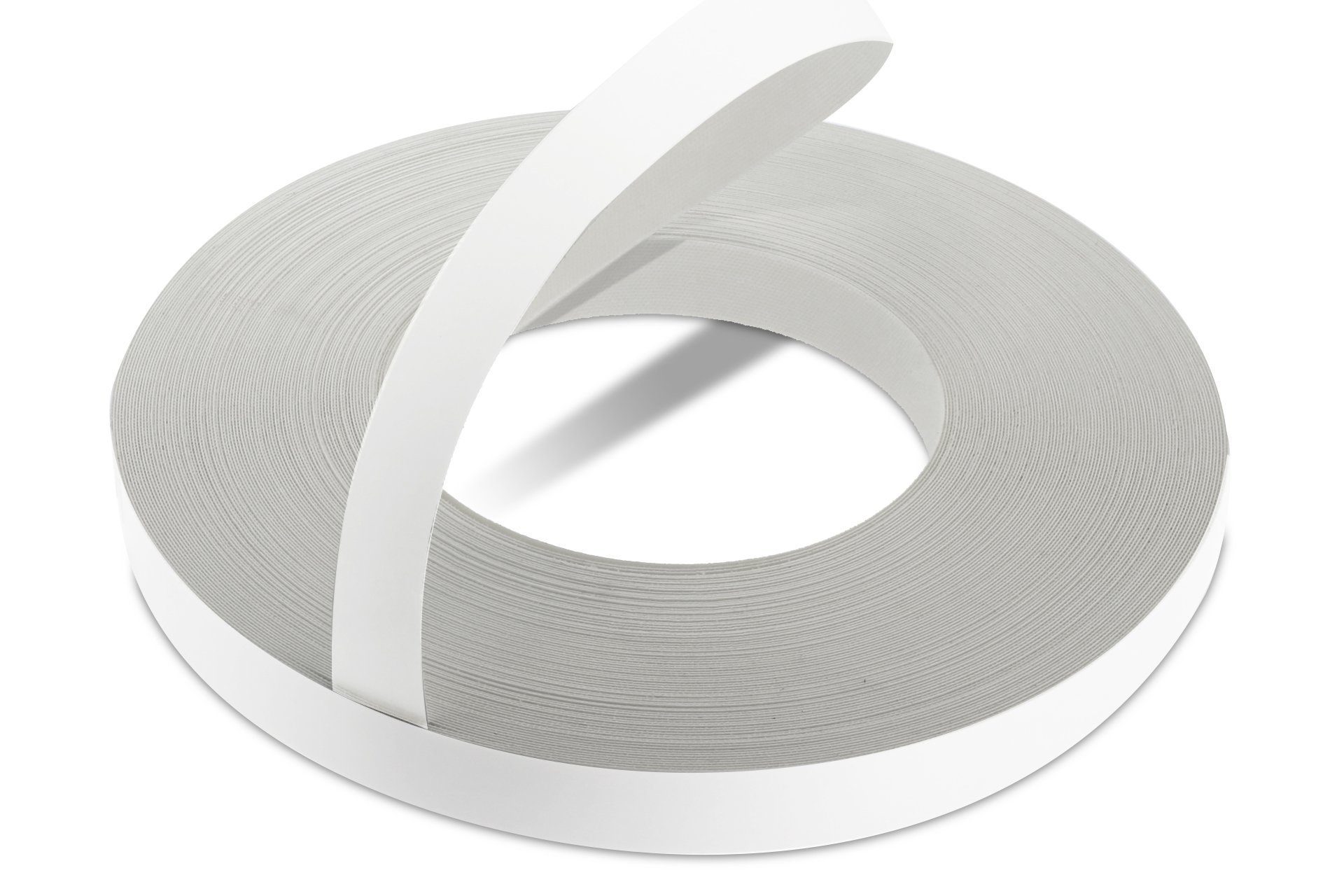

WoodPress® Matt White Melamine Pre-Glued Iron-On Edging Tape - 50m Trade Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT)

WoodPress® Matt White Melamine Pre-Glued Iron-On Edging Tape - 50m Trade Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT) -

WoodPress® Pearl White Melamine Pre-Glued Iron-On Edging Tape - 50m Trade Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT)

WoodPress® Pearl White Melamine Pre-Glued Iron-On Edging Tape - 50m Trade Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT) -

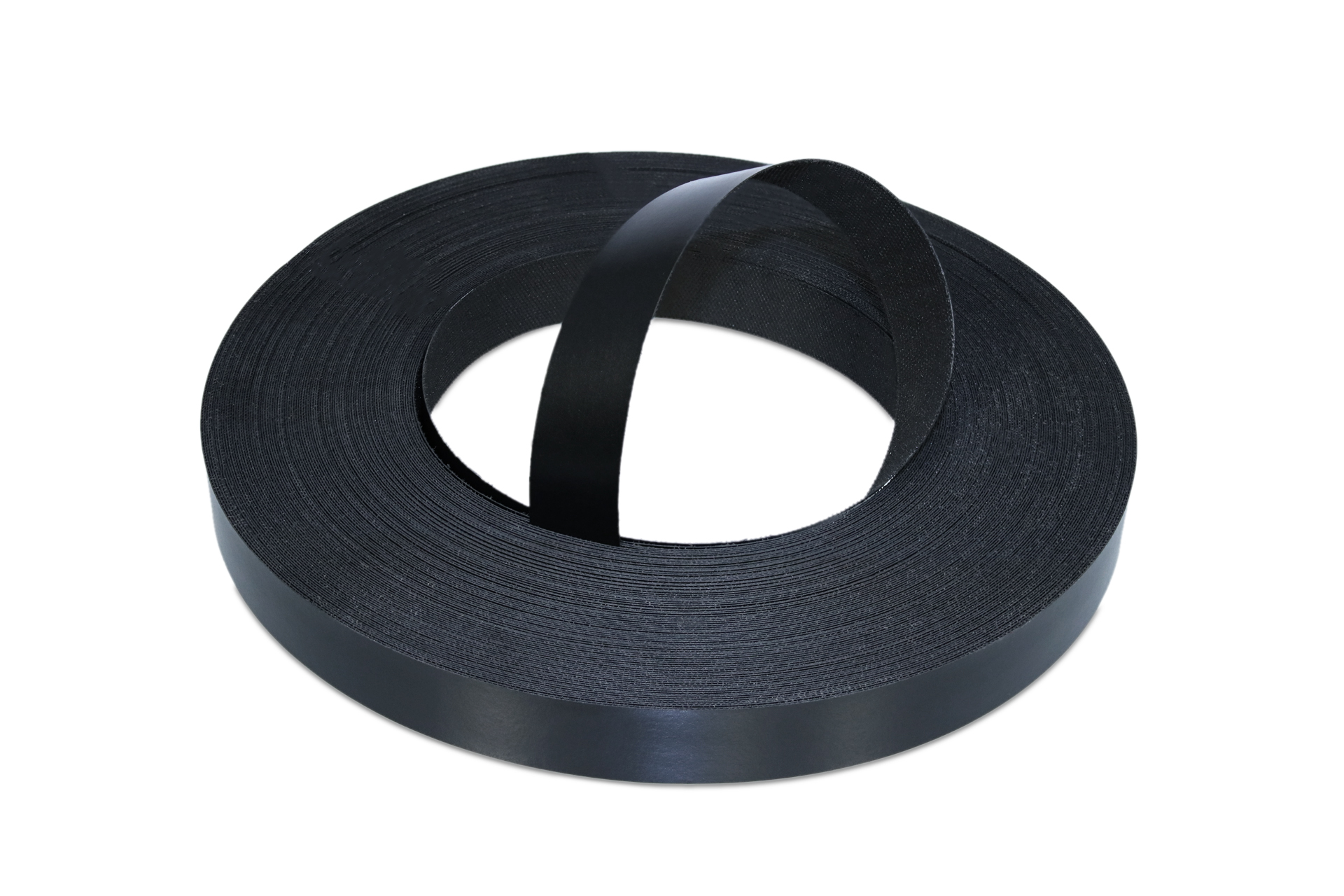

WoodPress® Matt Black Melamine Pre-Glued Iron-On Edging Tape - 50m Trade Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT)

WoodPress® Matt Black Melamine Pre-Glued Iron-On Edging Tape - 50m Trade Roll

£14.96 – £24.96 + VAT (£17.95 - £29.95 inc. VAT)

Starting a woodworking project? Choosing the right wood glue can feel overwhelming with so many brands and types available. Which one is best for your project? Then comes the endless hours of YouTube tutorials, user manuals, and trial-and-error learning before you even get started. But don’t worry! This guide breaks it all down—types of glue, their uses, and pro tips—to help you glue like a pro in no time!

Enjoy your read!

PVA Glue (Polyvinyl Acetate)

PVA glue is like the Swiss army knife of woodworking adhesives—versatile, easy to use, and available in different varieties tailored to various woodworking tasks.

Yellow Carpenter’s Glue: This is your go-to for most indoor woodworking projects. It dries hard, creates a strong bond, and works best with wood-to-wood connections.

White PVA Glue: A lighter version of carpenter’s glue, typically used for lighter wood applications or non-wood surfaces like paper or fabric.

Water-Resistant PVA: Ideal for projects that might come into contact with moisture, such as outdoor furniture.

Titebond III (Waterproof PVA): This one can handle water exposure, making it perfect for exterior woodworking projects. Plus, it offers superior strength while remaining non-toxic and easy to clean up.

Contact Adhesive

Also known as contact cement, this glue is a bit of a show-off in the adhesive world. It bonds almost instantly once the two surfaces come into contact, making it ideal for laminates, veneers, and large surface areas where traditional glue might not be practical.

Use Case: Applying a veneer to plywood or attaching laminate to countertops.

Caution: This glue is solvent-based and releases strong fumes, so make sure to work in a well-ventilated area.

Aliphatic Resin Glue

This glue is often mistaken for PVA because it’s similar but has a slightly stronger bond and better heat resistance. Aliphatic resin, often called “yellow glue,” is ideal for cabinet making and other fine woodworking projects.

Pro Tip: It dries quickly and sands down nicely, making it perfect for projects where smooth finishes matter.

Polyurethane Glue

Looking for something strong, versatile, and waterproof? Polyurethane glue might just be your new best friend. This adhesive excels at bonding different materials beyond wood, including metal, plastic, and ceramics. It requires moisture to activate, and as it cures, it expands to fill gaps, creating an ultra-strong bond.

Pro Tip: Since it expands, a little goes a long way—use sparingly and clamp your pieces tightly to prevent gaps or misalignment.

Epoxy

If you need strength and durability, epoxy is your go-to. This two-part adhesive (a resin and a hardener) forms an incredibly strong bond, making it perfect for structural joints and repairs. Epoxy is also waterproof, making it ideal for projects like boat building or outdoor furniture.

CA Glue (cyanoacrylate or superglue)

CA glue is the speed demon of adhesives. It’s perfect for quick fixes or holding pieces together while the real glue dries. It’s especially useful for small joints or fine details.

Hide Glue

Hide glue is a classic—literally. It’s been used for centuries in fine woodworking and instrument making. The two main types are liquid hide glue, which is pre-mixed and easy to use, and hot hide glue, which requires heating before application. Hide glue is reversible with heat and moisture, making it a favorite for antique restorations.

Use Case: Furniture repair or restoration, particularly with antiques.

Hot Melt Glue

Hot melt glue is best known for crafting but has its place in woodworking, particularly for temporary jigs or quick projects. It bonds instantly as it cools, making it convenient for holding small, non-structural parts.

Use Case: Securing parts temporarily or working with lightweight materials.

Caution: Be careful with hot glue guns—both the glue and the gun itself can cause burns.

Spray Adhesives

Spray adhesives are perfect for lightweight materials like fabric, foam, or thin wood veneers. It’s an easy-to-apply adhesive, usually in an aerosol can, that provides an even coat over large surfaces.

Use Case: Upholstery, foam projects, or attaching lightweight veneers.

Caution: Ventilation is crucial—many spray adhesives contain harmful solvents.

Construction Adhesives

When you’re working on big, heavy-duty projects like building a deck or framing a house, construction adhesives are your best bet. These glues bond almost anything, from wood to brick to metal, and they’re designed for strength and durability.

Plastic resin glue

This powdered glue is mixed with water before use and creates a very rigid, waterproof bond. It’s typically used for large, outdoor projects or furniture building, where you need serious strength.

Use Case: Outdoor furniture, cabinetry, or boat building.

Caution: Requires precise mixing and can be messy to work with.

Extended Time Glues

For large or intricate projects that require more assembly time, extended-time glues provide a longer open time, allowing you to reposition parts before the glue sets. This is especially useful when working on complex joints or large-scale projects.

Glue’s shelf life: each glue has a different shelf life, while PVA glue can last 12-24 month after being opened whereas polyurethanes glue only lasts up to 6 months. Read the bottle for storing advice because not all glues need to be stored the same; this is important for both shelf life and safety.

Choosing the Right Clamps:

Applying adequate clamping pressure is crucial when gluing wood. Different clamps provide different levels of pressure, so understanding which clamp to use is essential.

Bar clamps: Ideal for large panel glue-ups, providing a wide, even distribution of pressure.

Pipe clamps: Similar to bar clamps, but with adjustable lengths, perfect for long boards.

F-clamps and C-clamps: Great for smaller projects or holding pieces in place for more intricate work.

Parallel clamps: Provide even pressure distribution, making them ideal for precise tasks like cabinet making.

Clamping Pressure: How Much is Enough?

When gluing wood, it’s essential to apply enough pressure to ensure a strong bond without squeezing out too much glue. Tighten the clamps until a small amount of glue squeezes out of the joint—this indicates that enough adhesive remains inside the wood fibers for a strong bond.

Handling Glue Squeeze-Out:

Glue squeeze-out is inevitable but manageable with the right approach:

Tape method: Place masking tape along the joint line before applying glue. After clamping, peel away the tape for a clean, glue-free edge.

Damp rag: Wipe away excess glue with a damp cloth right after clamping. Avoid rubbing glue into the wood grain, which can affect finishing.

Scraper: For dried glue, use a scraper or chisel to remove the excess cleanly.

So, Which Glue is Best for You?

Before deciding which wood glue to buy, take a look at the materials you’ll be using and the techniques you will be applying in your project. It is also good to assess the necessary durability of the project and how much moisture it will be around. Once you have determined these factors, you can always refer back to this blog to choose the perfect wood glue for you.

The right glue can be the unsung hero of your woodworking project, ensuring it stays strong and lasts for years to come. Now that you know the different types, go ahead—glue your next masterpiece with confidence!